Barre latérale du produit

Barre latérale du produit

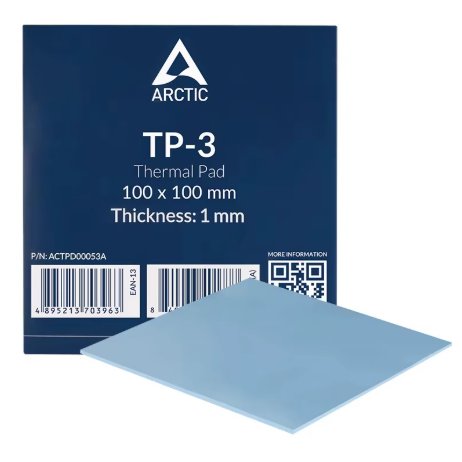

Arctic TP-3 Pad Thermique

- Prix habituel

- 3,990 DA

- Prix soldé

- 3,990 DA

- Prix habituel

-

Impossible de charger la disponibilité du service de retrait

Partager

High Performance — Very Soft

Based on silicone and a special filler, TP-3 outperforms high-performance pads, especially when height differences of closely spaced chips typically occur due to manufacturing tolerances. The TP-3 offers excellent thermal conductivity despite extremely low hardness.

Minimization of Thermal Resistance

The thinner the pad, the lower the thermal resistance. The TP-3 pad with a thickness of 0.5 mm can easily be compressed to 0.3 mm and thus compensate for height differences between various components of up to 0.2 mm. Please note that due to the extremely low hardness, the installation of the 0.5 mm pad requires extra care. Please refer to the user manual.

Versatile Applications

Heat-conducting, vibration-damping, mouldable, electrically insulating — safe and easy to use. Thanks to its good compression properties, the soft heat conduction pad is particularly gentle on components and at the same time a good heat conductor. In addition to the standard format for M.2, the TP-3 is available in various sizes and thicknesses, which can be easily cut to the desired shape and size. This makes it ideal for RAMs, chipsets, and ICs of all kinds, which are used in PCs, laptops, consoles, graphics cards, and electronic devices in general.

Safe Handling

The ARCTIC TP-3 is electrically insulating, non-adhesive, and easy to handle. This means that optimal and safe heat transfer can be ensured in many application areas.

Bridging Gaps

The TP-3 is softer than conventional pads and therefore particularly suitable for different chip heights and possible tolerances. Thanks to their good compressibility properties, the thermal pads act as the perfect gap filler and bridge uneven surface and air gaps without stressing sensitive and protruding components.

Stackable without Performance Loss

The ARCTIC TP-3 thermal pads can be stacked particularly well due to their softness and low Interfacial Contact Resistance. This allows for flexible adaptation to various application requirements and the bridging of different thicknesses without compromising the efficiency of heat transfer. In contrast, harder pads often lose performance when stacked.